WHEN DO GGB SELF-LUBRICATING BEARINGS OPERATE WITH A LUBRICANT?

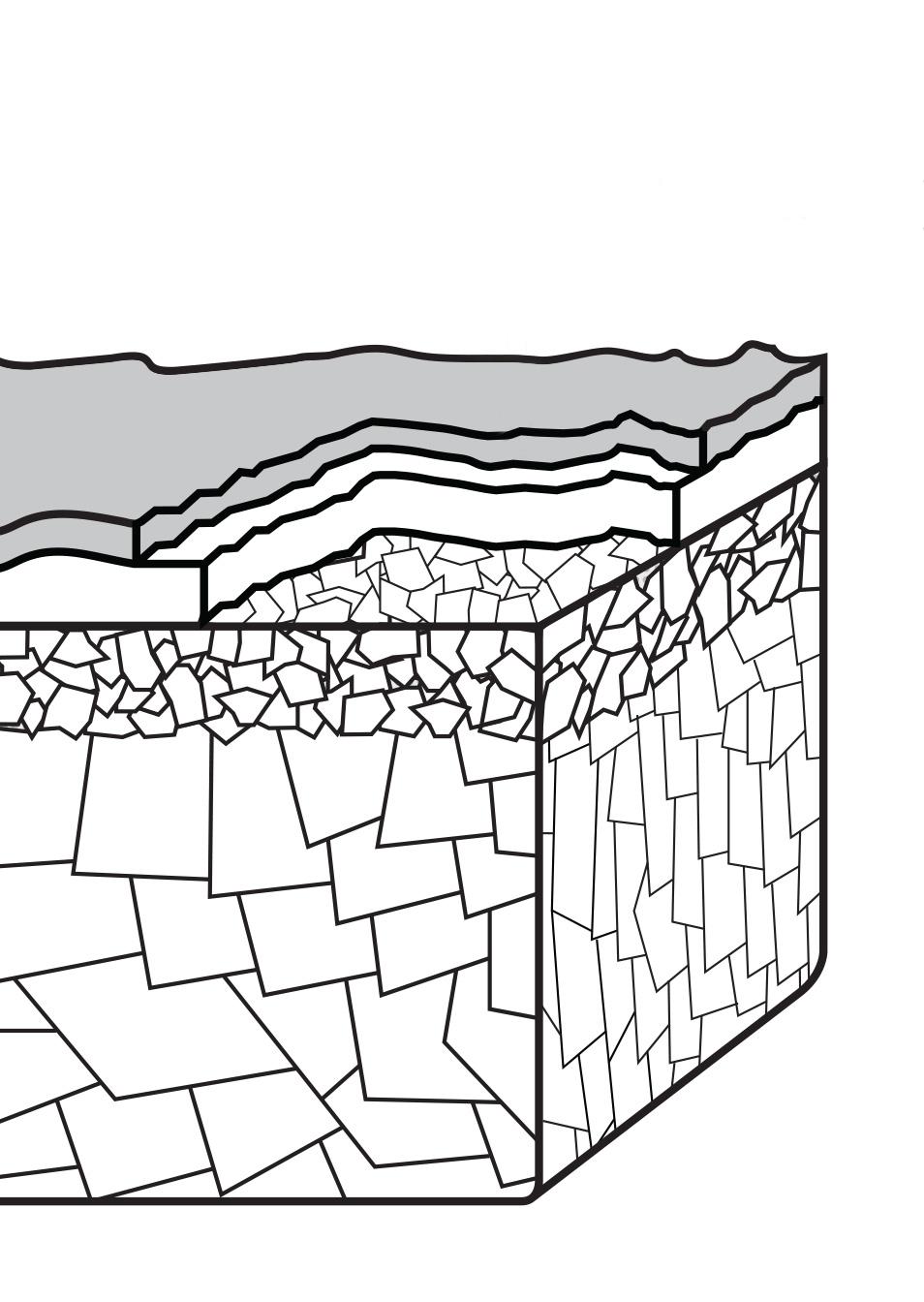

Self-lubricating bearings are also necessary when operating under boundary or marginally lubricated regimes.

These regimes occur when the thickness of the lubricant film is too low to avoid metal-to-metal contact and wear between the bearing and the sliding surface due to a combination of high loads, low speeds and insufficient lubricant viscosity.

For equipment running under periods of low speed idling and frequent stop-start operation, the self-lubricating properties of GGB bearings significantly improve machine efficiency by reducing bearing wear and the increase of clearances, noise and the risk of eventual equipment seizure.

Lubricated Operation