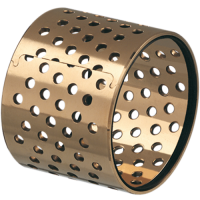

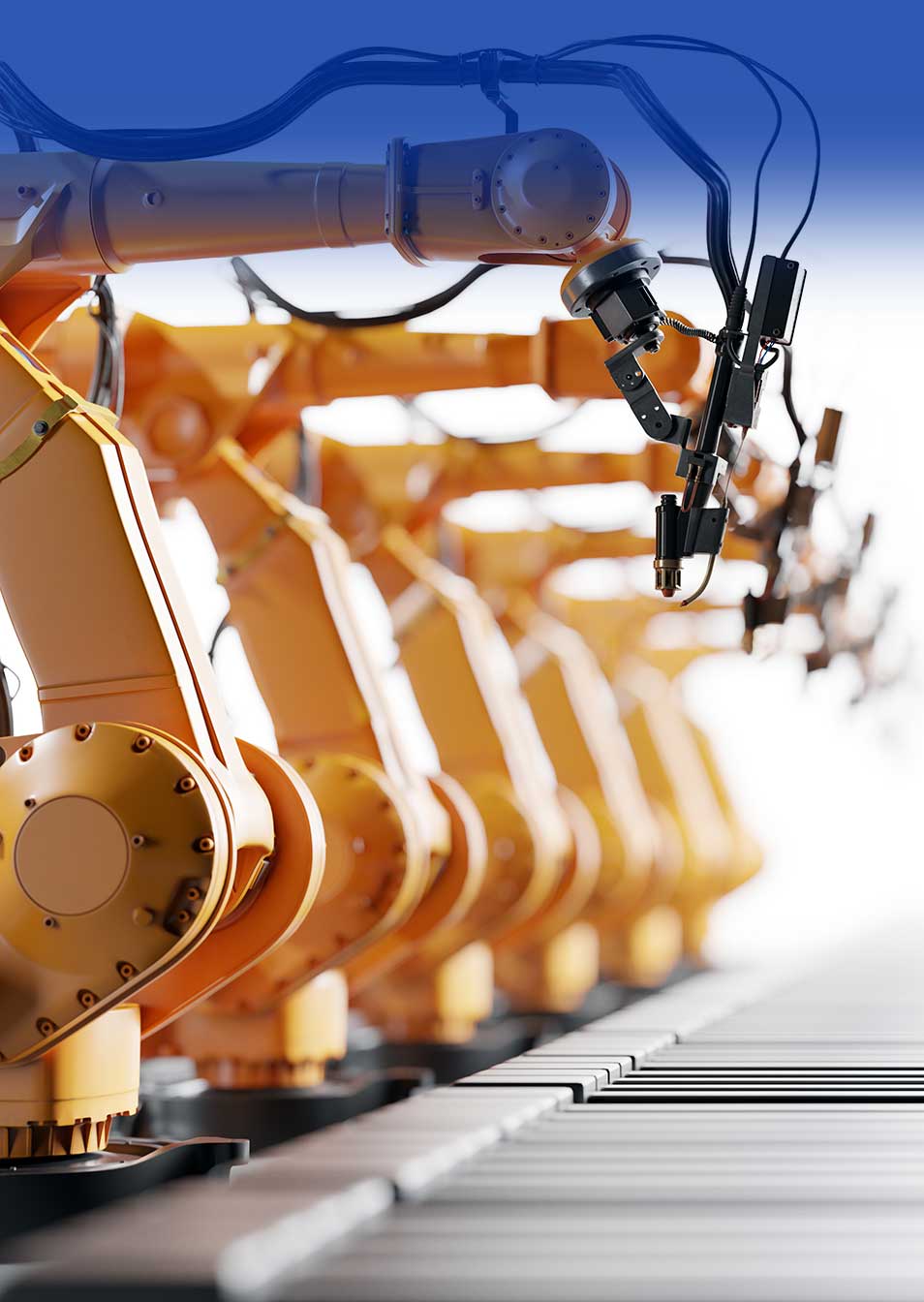

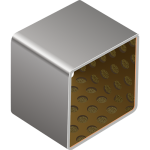

GGB tribological solutions move the industrial world one step closer to the future. Our products are used in tens of thousands of critical applications every day—around the planet. Our goal is to provide reliable, maintenance-free surface solutions for almost any application—no matter where those demands take our products.