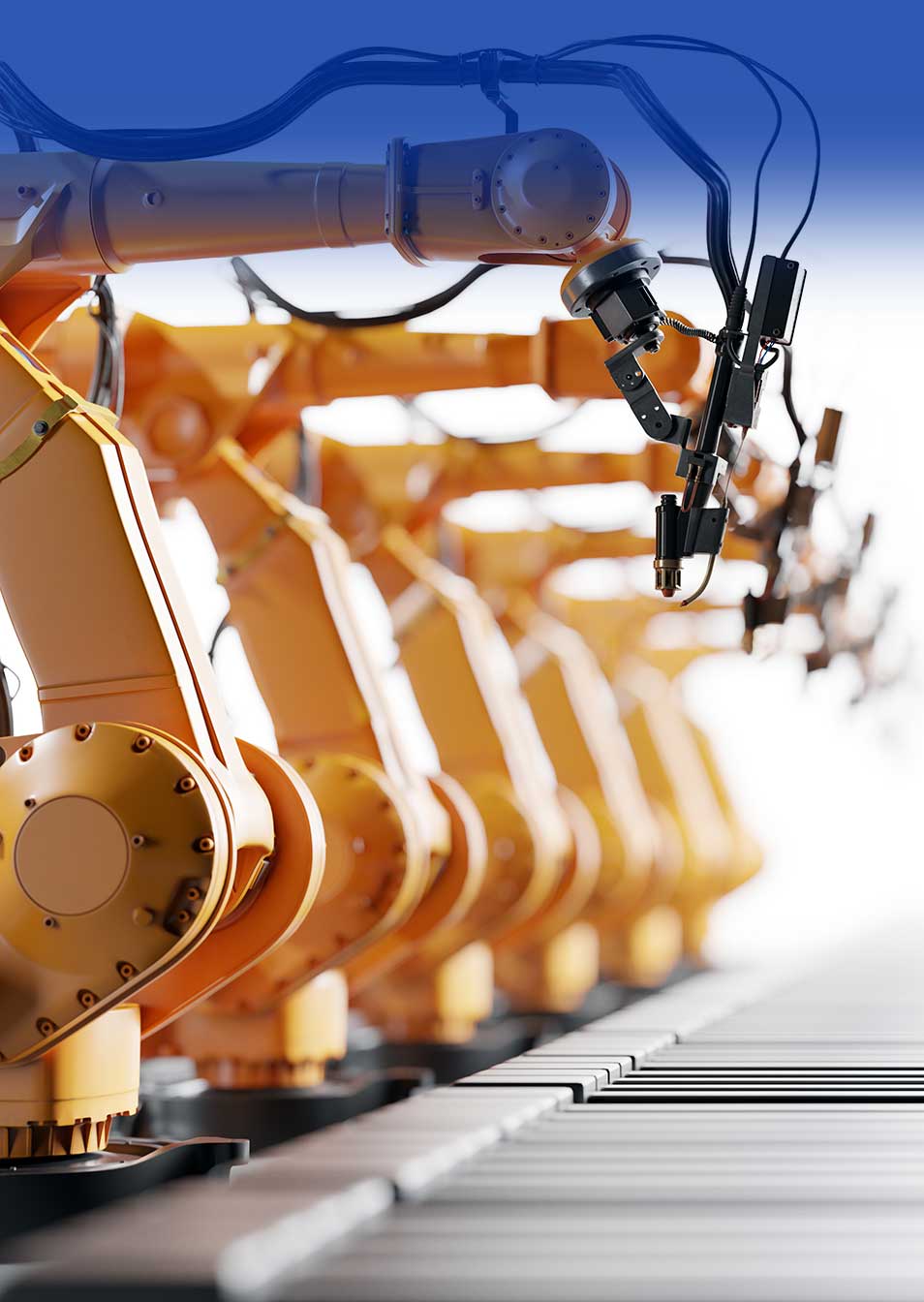

- Good bearing performance in dry working conditions

- Good performance in lubricated or marginally lubricated applications

- Corrosion resistant in humid/saline environments

- Suitable for very high temperature applications

- Very good weight performance ratio

- Within injection moulding tool feasibility unlimited dimensions and design features

- Compliant to ELV, WEEE and RoHS specifications

-

Approved to standard FAR 25.853 and FAR 25.855 (Federal Aviation Regulations) and ASTM E162:2016 – surface flammability testing for aircraft interior applications

-

Tested acc. to ASTM E595/ECSS-Q-ST-70-02C - Outgassing properties of materials used in Spacecraft equipment

AVAILABILITY

Bearing forms available in standard dimensions

- Plain cylindrical bushes

- Plain flanged bushes

EP®63 Bearing forms made to order: standard forms in special dimensions, thrust washers, half-bearings, sliding plates, customized bearing designs