Applications

We know there's no "one-size-fits-all" approach to efficiency. That's why we're always looking for new ways to tailor our products to meet a wide variety of applications—and these efforts are routinely met with outstanding results. Here are a few industries we've adapted our solutions for:

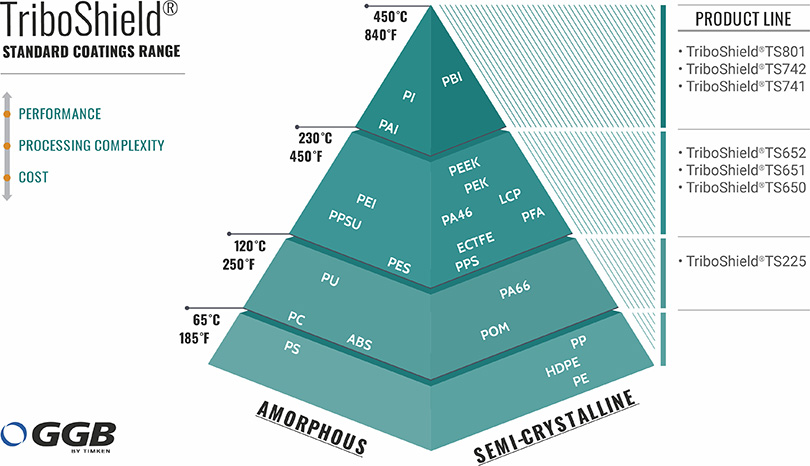

GGB TriboShield® coatings are specifically formulated to be self lubricating and provide the full range of thermal, mechanical and tribological possibilities that today's polymers can offer.

Offers burr-free application to meet stringent cleanliness requirements and are used in door hinges, convertible roof mechanisms, steering and seating systems.

TriboShield® coatings are versatile enough to provide tribological solutions in a wide variety of applications, from cranes, transportation chains, and solenoids to baby strollers and medical devices (such as dialysis pumps, display mounts, and more).

GGB is the only true global one-stop solution provider of tribological coatings, covering the full cycle from materials science, formulation, tribological expertise, coating production and coating application.

GGB can offer development and design expertise, apply and supply fully finished coated solutions, all with a global reach.