- DU® self-lubricating split bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

- Bushing material suitable for lubricated applications

- Anti-friction bearing suitable for linear, oscillating and rotating movements

- Approved to standard FAR 25.853 and FAR 25.855 (Federal Aviation Regulations) and ASTM E162:2016 – surface flammability testing for aircraft interior applications

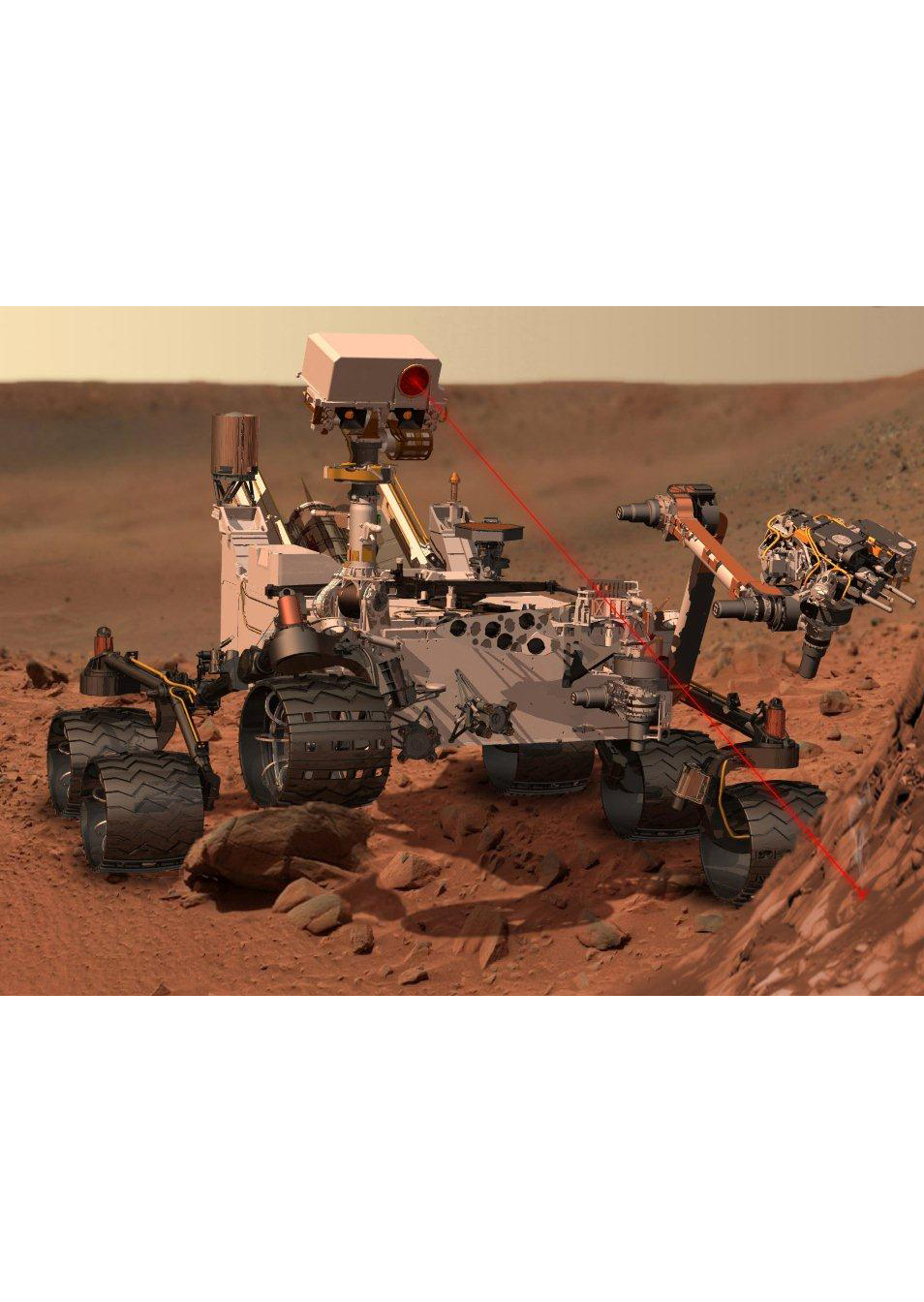

- Tested acc. to ASTM E595/ECSS-Q-ST-70-02C - Outgassing properties of materials used in Spacecraft equipment

- Approved to standard DIN EN 1797 and ISO 21010 (Cryogenic Vessels – Gas/Material Compatibility) for piping, valves, fittings and other components in both gaseous and liquid oxygen for up to maximum temperature of 60°C and oxygen pressure of 25 bars. Contact GGB for further details.

AVAILABILITY

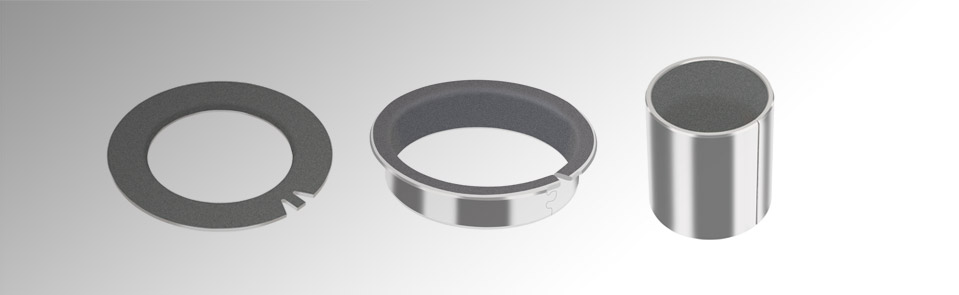

Bearing forms available in standard dimensions

- Cylindrical bushes / split bushings

- Flanged bushes / flanged split bushings

- Thrust washers

- Flanged washers

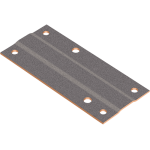

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs.

For a lead-free alternative material please visit our DP4® bearings webpage.

GGB retains the exclusive rights to market metal-polymer bearings designated DU® and DX®, which are protected under international trademark laws. Only GGB and its global network of distributors are authorized to market these products as such, so beware of counterfeits which are not produced to GGB´s exacting standards of quality and performance.