Bearing Application Requirements

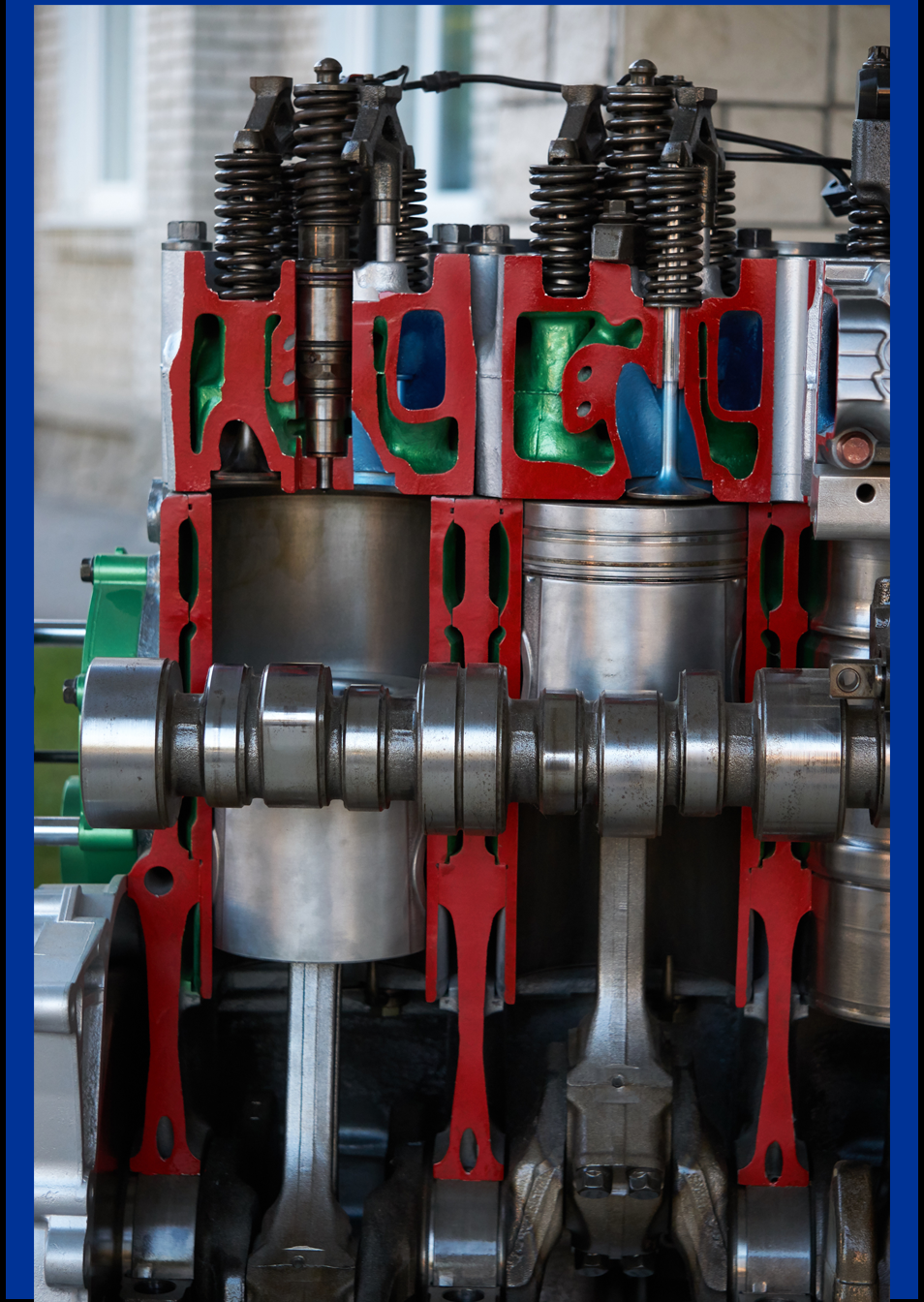

Variable displacement axial piston pumps are used in high power hydraulic systems in many industries, including aerospace, automotive, construction equipment, agricultural equipment, machine tools and others.

These pumps provide a variable flow to system actuators from zero to their maximum capacity. The variation in flow is effected by the change in position of the swash plate.

GGB Piston Pumps & Motors Bearing Solution

The technical requirements for a plain bearing in this application and specific function are among the most demanding of any high power hydraulic component.

In addition to temperatures ranging from -50°C to +140°C and wide range of lubricant viscosities, the cradle bearing must be able to withstand extreme, high load oscillating speeds and boundary lubrication conditions. This requires the bearing to offer high resistance to wear, fatigue and flow erosion.

GGB Fluid Power Bearings - Benefits

Compared with bimetal bronze bearings, high precision HI-EX® bearings offer the following advantages:

- Long service lives as the addition of PEEK (polyether ether ketone) in the bearing overlay provides excellent wear resistance under a wide range of load, speed and temperature conditions

- Lower friction with the addition of PTFE (polytetrafluoroethylene) in the bearing overlay for better response in flow variation for improved efficiency

- Lead-free bearing material compliant with EVL directive and RoHS and WEEE regulations