Advantages of GGB Tribological Materials

Self-lubricating materials that require no added lubrication resulting in less downtime and longer periods of time between regular maintenance. In addition to self-lubricating, our materials can handle mis-alignment that is frequently seen in hydro environments

Environmentally Friendly Materials (RoHS complaint) - Greaseless, lead-free GGB materials comply with stringent environmental regulations and will not cause damage to our environment or contaminate our waterways

Excellent Wear Resistance/Extended Service Life – Materials that offer excellent wear resistance resulting in longer service life between maintenance.

Corrosion Resistance – Materials that can outlast competitors and resist corrosion for smooth operation in harsh weather conditions and offshore corrosive environments.

GGB Bearing Solutions for Hydro Applications

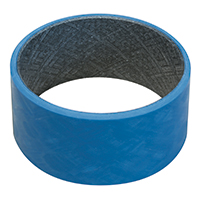

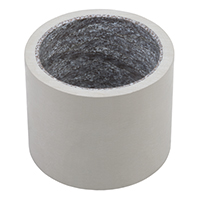

GGB's HPMB®, HPM, and HPF high load, self-lubricating fiber reinforced composite bearings meeting the challenges most hydropower applications face.

- Maintenance-free operation

- Low friction operation

- Outstanding dimensional stability

Due to negligible water absorption GGB HPM, HPMB and HPF® bearings do not require additional running clearance due to the water exposure. The flexible nature of the liner allows bearings to tolerate misalignment conditions without damage, which gives GGB HPM, HPMB and HPF undisputed benefit over metallic bearings in water turbines.

GGB’s HPMB offers the flexibility of being machined in the field making it a great option for hydro refurbishment projects.

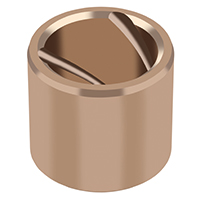

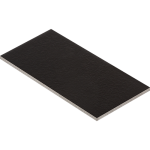

GGB’s self-lubricating and maintenance-free CBM and CSM materials were designed for applications with high specific loads, long idle times under static load and low sliding speeds. These features make these materials useful in hydropower applications where a lubricant free material with little to no maintenance is required.

GGB’s DB bearing material meets the needs of numerous hydromechanical applications with its maintenance-free operation, high load capacity, low wear rate, reduced running clearance and negligible stick-slip effect. These features lead to DB use in segment, miter and emergency gates, as well as slewing rings and more.

GGB Tribological bearing materials are US Army Corps of Engineers approved.

Download our Brochures: