The Magic of Paired Performance

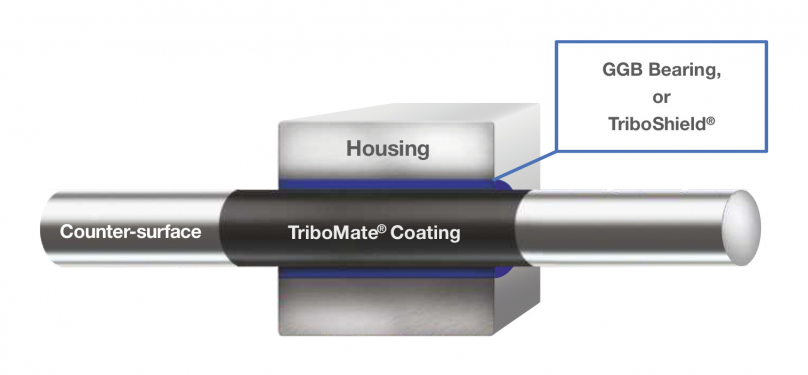

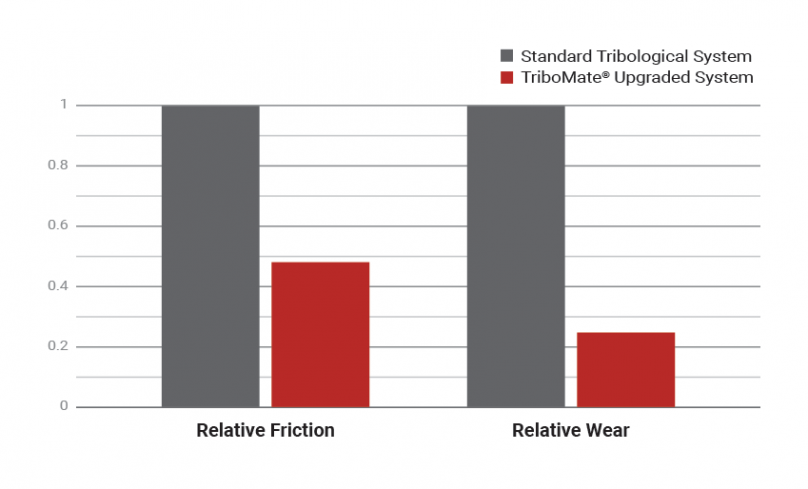

We know there is no “one-size-fits-all" approach to efficiency. That’s why we offer TriboMate paired solutions, the tribological answer that helps you reach the next generation of system performance. A customized range of coatings that work with other polymer surfaces, TriboMate assists in overcoming challenges such as:

Fretting Wear Resistance

GGB's polymer coatings provide intrinsic solid lubrication, making it ideal for eliminating vibratory wear. Our TriboMate paired coatings are designed to interact with GGB's conventional polymer-based bearing materials as well as our TriboShield® solutions, all leading to a significant extension of service life—even in the most demanding conditions.

Self Lubrication Solution

Incorporate solid lubricants to deliver self-lubricity that can help reduce and sometimes eliminate the need for additional lubrication in machine parts and reduce reliance on third-party oils or greases.

Part and Component Reduction

TriboMate provides tailored friction levels for many complex-shaped surfaces that traditional cylindrical bearings alone cannot access, allowing for a more simplistic design that employs fewer parts and easier assembly—and fewer part failures.

Corrosion Protection

When it comes to corrosion resistance, TriboMate can significantly increase chemical resistance for longer wear life, offering a barrier of inert material between surfaces to extend longevity.

Versatile

TriboMate can be seamlessly paired with other TriboShield® polymer coatings, as well as GGB tribological plain bearing solutions including our Engineered Plastics bearings, thermoplastic-based Metal-Polymer products (DX®, DX®10, HI-EX®, DS, DTS10®) and our GAR-FIL bearings.

Hard Chrome Replacement

With high toxicity levels, high costs, and more bans likely coming in the next decade —chemical hard chrome plating is becoming a thing of the past. The environmentally conscious way of the future is TriboMate paired coatings. Contact your local Application Engineer for additional information.

Seat Suspension System

Seat Suspension System  Linear Reciprocating Motion

Linear Reciprocating Motion  Passive Exoskeleton

Passive Exoskeleton  Crane Grease Elimination

Crane Grease Elimination  Prosthetics

Prosthetics