- Self-lubricating metal bearings produced by metallurgic powder

- Maintenance-free bearings with homogeneously distributed solid lubricant (graphite, MoS2) in the metallic matrix

- High load capacity and temperature ranges up to 600°C possible depending on the alloy

- Corrosion resistant alloys are available

- Lead free alloys are available

AVAILABILITY

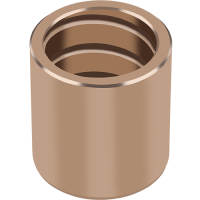

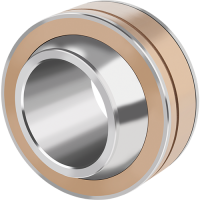

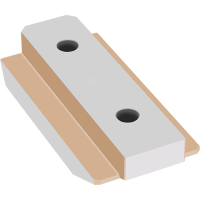

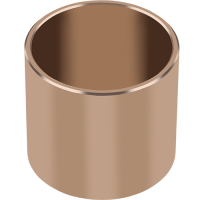

Bearing forms made to order: cylindrical bushes, flanged bushes, thrust washers, sliding plates, half-bearings, axial and radial segment rings, self-aligning spherical bearings, spherical plain bearings, special shapes, customized bearing designs

GGB-CSM® bearing material is known by various names such as CSM or GGB CSM. Buying a GGB-CSM® bearing from GGB or its authorized distributors guarantees that you do not receive a counterfeit product.