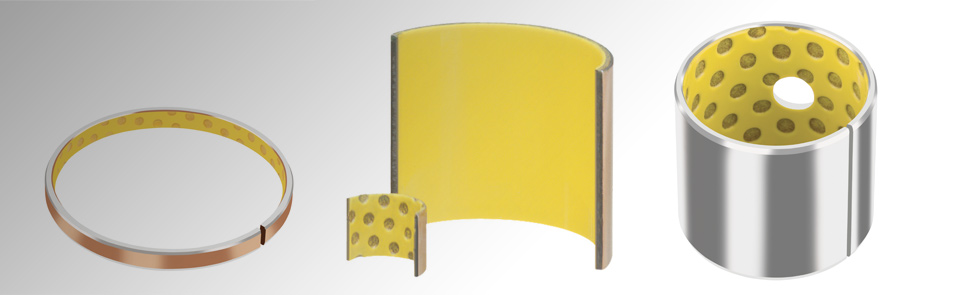

- DX marginally lubricated bushings for grease or oil lubricated applications

- Standard split bushings contain grease indents in the sliding layer; plain sliding layer available by request

- Optimum performance under relatively high loads and low speeds

- Suitable for linear, oscillating and rotating movements

- Wide range of parts available from stock

AVAILABILITY

Bearing forms available in standard dimensions

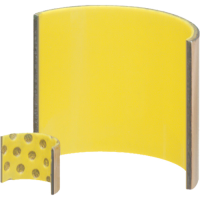

- Cylindrical bushes / split bushings

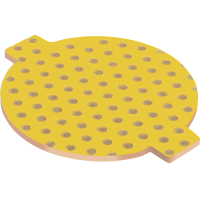

- Thrust washers

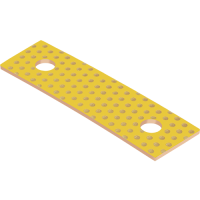

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs

GGB retains the exclusive rights to market metal-polymer bearings designated DU® and DX®, which are protected under international trademark laws. Only GGB and its global network of distributors are authorized to market these products as such, so beware of counterfeits which are not produced to GGB´s exacting standards of quality and performance.