- Good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

- Very good performance in lubricated applications

- Good performance in greased applications

- Suitable for linear, oscillating and rotating movements

- Bronze back offers improved corrosion resistance in humid/saline environments

- Lead-free material compliant to ELV, WEEE, and RoHS specifications

- Tested acc. to ASTM E595/ECSS-Q-ST-70-02C - Outgassing properties of materials used in Spacecraft equipment

AVAILABILITY

Bearing forms available in standard dimensions

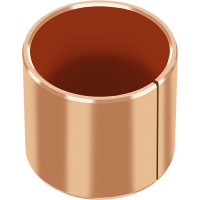

- Cylindrical bushes

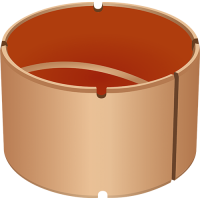

- Flanged bushes

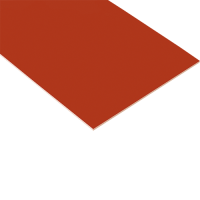

- Sliding plates

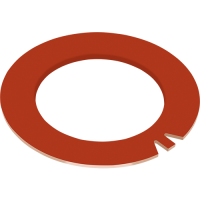

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, bearings with locating notches, lubricant holes and machined/stamped grooves