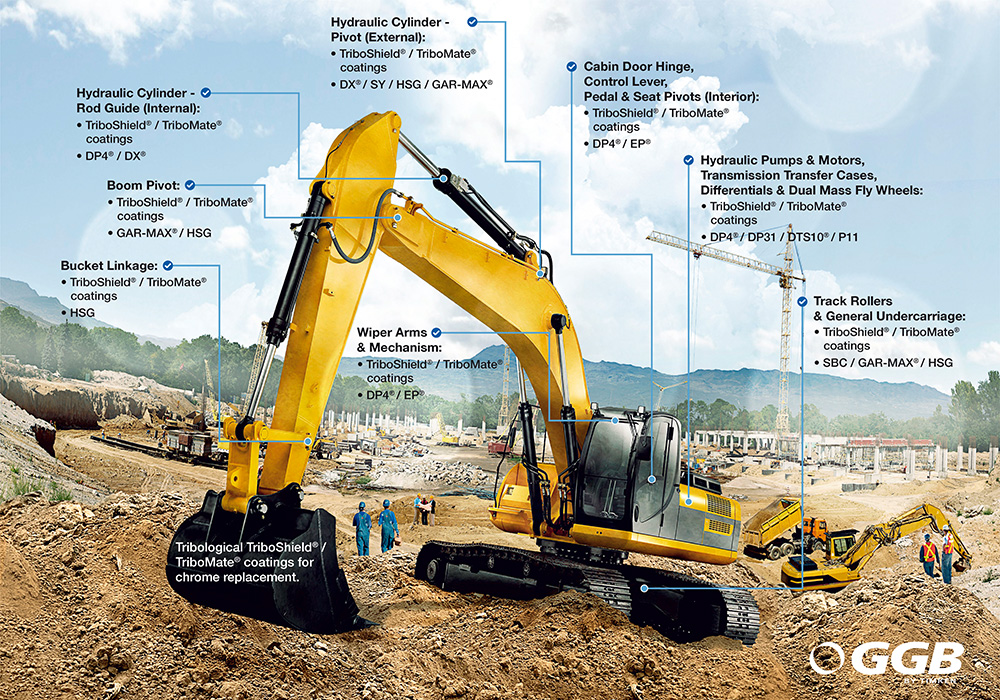

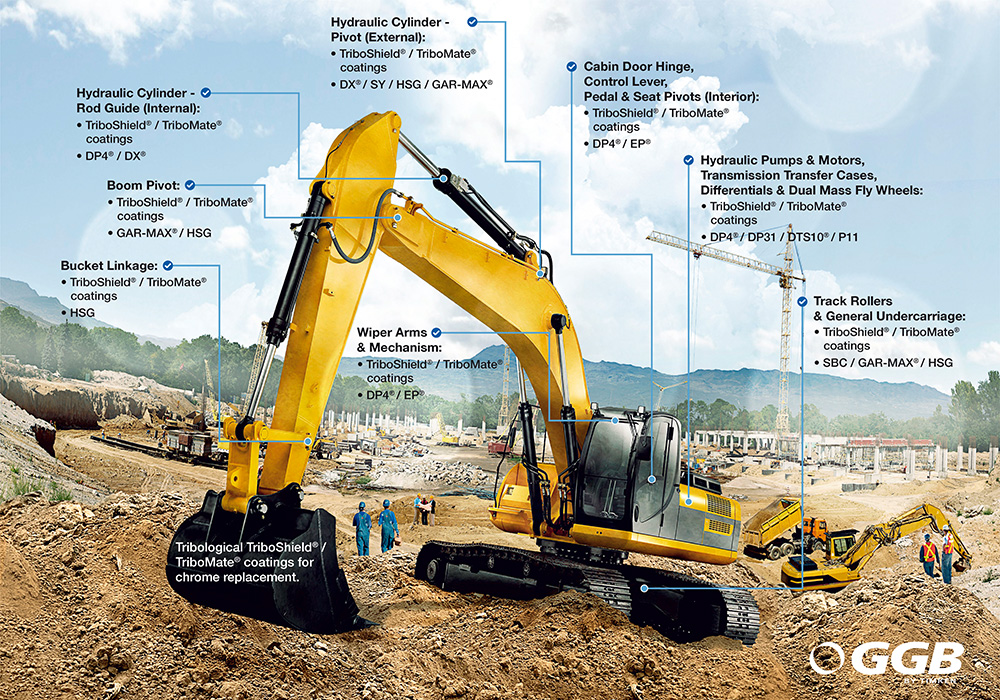

We understand that long lasting performance in rugged environments and dependability of your bearings are big pain points for manufacturers of construction and other off-highway equipment. At GGB, we offer reliable greaseless solutions as well as greased bronze and steel bearing solutions designed to increase service life and uptime and enhance sustainable progress and living standards—all at a lower cost of ownership.

Tough jobs demand even tougher surface solutions

Machine downtime for a difficult repair, replacement or even just to lubricate a joint can be expensive and time consuming. GGB has worked with major off-highway OEMs and the Advanced Manufacturing Institute (AMI) to develop innovative surface solutions designed to reduce this maintenance time in a variety of applications.

Applications

- Articulating Joints

- Axle Trunnions

- Blade Leveling Cylinders

- Bucket Pivots

- Conveyors

- Crawlers

- Critical Clearance Joints

- Drill Pivot

- Dump Body Pivot

- Dumpers

- Frame/Walking beam Trunnion

- Kingpins

- Lift Cylinders

- Linkage Pins

- Motor Graders

- Rock Shaft

- Skid Steers

- Steering Cylinders

- Suspension or Track Trunnions

- Transmissions

- Wheel Pitching Mechanisms

Eliminate Grease to Reduce Maintenance

- Self-lubricating GGB bearings are ideal for applications with inadequate or no lubrication.

Increase Performance and Extend Service Life

- Superior wear resistance and high shock load capacity result in extended service life, while low friction properties reduce power losses for improved equipment performance.

Reduce Systems Costs

- GGB's tribological solutions eliminate the need for hardening and machining grease paths, while also offering a one-piece construction for space and weight savings and simplified assembly.

Lower Environmental Impact

- Greaseless, lead-free GGB surface solutions comply with increasingly stringent environmental regulations.

Designed for your specific application

GGB’s extensive range of standard or custom surface solutions for various construction applications offer numerous benefits like safety, bigger load capacity, higher shock resistance, lower weight and quieter operation than traditional roller bearings.

Solutions for demanding construction applications

Our self-lubricating bushings for heavy construction provide excellent performance, durability and resistance to heavy loads and wear and fatigue. Since lubrication is eliminated, equipment no longer needs to be taken out of operation to be serviced, saving you time and money.