Bearing Application Requirements

Given the tight constraints – regulatory, engineering, and cost-related – surrounding electrified train and streetcar projects, finding even minute ways to reduce weight can pay big dividends in the long run.

For example, a pantograph is a jointed framework that conveys current to a train or streetcar.

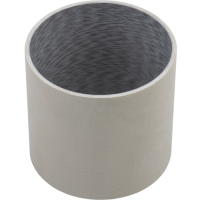

Plain bearings are employed in the hinge points of pantographs to ensure constant contact with electric lines, and GGB’s MLG self-lubricating fiber reinforced composite bearing offers a lightweight solution with myriad ancillary benefits.

GGB Railroad Bearing Solution

MLG is a value-engineered, filament-wound bearing for lighter-duty applications (like trains and streetcars) that still require the shock, misalignment, and chemical resistance of fiber-reinforced composite bearings.

MLG self-lubricating plain bearings have the same operating temperature range (-195°C to 160°C) as our high-end fiber-reinforced composite solutions, and feature similar low-friction and high-load capacity.

GGB Plain Bearings for Railway Applications - Benefits

Using MLG filament wound plain bearing for your pantograph offers the following benefits:

- Reduced application weight through lightweight, compact bearing design

- Electrical insulator stopping unwanted noise and static

- Good resistance to shock loads, shaft misalignment, and abrasion

- Lubricant free, low-friction operation

- Resistance to corrosive environments

- Reduced ownership cost through both maintenance-free operation and long-lasting bearing design

- Made in the USA