Bearing Application Requirements

Due to the extreme physical forces inherent in the operation of train cars, railway operators have very little margin for error, both financially and in terms of safety.

Whether it manifests itself as the catastrophic failure of a single part, or the long-term degradation of countless parts, financial peril is never far away, and only those who take a proactive approach that maximizes service life – and therefore safety and profitability – will survive and thrive.

For example, the constant pushing and pulling between train cars during operation subjects train couplers to extreme loads. To protect couplers from damage, draft systems act like large shock absorbers, accommodating these pushing and pulling forces and minimizing side-to-side movement of the coupler arm to ensure proper alignment during transit.

Draft systems make it possible for trains over a mile in length to haul untold tons of consumer goods safely and efficiently – and GGB’s contribution to draft systems, DP4® metal-polymer low-friction bearings, increases comfort, safety and efficiency further still.

GGB Railway Bearing Solution

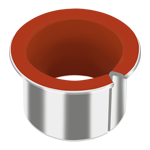

DP4® plain bearing consists of a steel backing to which is bonded a porous sinter bronze interlayer. The interlayer is overlaid and impregnated with PTFE containing a mixture of inorganic fillers and special polymer fibers. The steel backing provides mechanical strength while the bronze sinter layer offers a strong mechanical bond for the filled bearing lining.

GGB Low-Friction Plain Bearings for Railway Applications - Benefits

Using DP4® low-friction plain bearings in draft system applications provide the following benefits:

- Increased service life and minimized maintenance due to its unique metal-polymer composition

- Suitable for linear, oscillating and rotating movements

- Low-friction bearing performance over a wide range of loads, speeds and temperatures in dry running conditions

- Very good performance in lubricated applications

- Good performance in greased applications

- Lead-free product compliant to EVL, WEEE, and RoHS specifications

- Made in the USA