Bearing Application Requirements

Refuse collection vehicles operate 8 hours a day, 365 days a year. The articulating packing mechanisms at the rear of these vehicles are designed to withstand dusty, dirty, heavily loaded, low-speed cyclical operating conditions.

To make the process cleaner and more efficient, the manufacturer wanted to replace the mechanisms’ greased brass/bronze bushings and pins that would fail prematurely if not continually regreased.

GGB Industrial Plain Bearing Solution

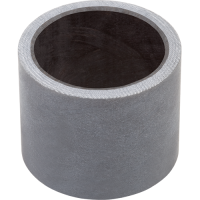

HSG (High Strength GAR-MAX®) heavy-duty bearings were tested for their ability to withstand the magnitude of the loads involved in the application. With a static load capacity of 415 MPa, the self-lubricating, maintenance-free bearings were more than capable of handling the extreme loading conditions.

In addition, these industrial bearings provide excellent shock load resistance, low friction performance and high wear resistance under slow oscillating movements or rotating speeds.

GGB Heavy-Duty Bearings - Benefits

The results of field trials indicated a considerably longer service life with HSG heavy-duty bearings.

Other benefits included:

- Improved efficiency and reduced costs from the elimination of downtime for maintenance

- More environmentally friendly solution with the elimination of grease coming into contact with the refuse

- Global cost gain compared to bronze bushings and brass bearings